Application:

- High Current power converters

- DC to DC power conversion

- Current Noise Filter

- Product: PC/Notebook/Server Application Smartphone, wearable device, Notebook, Server, Networking/Telecom

|

Grade |

Chemical Composition(%) |

||||||||

|---|---|---|---|---|---|---|---|---|---|

C |

Si |

Mn |

Ni |

Cr |

Mo |

Cu |

Nb |

Fe |

|

304L |

≤0.03 |

≤1.0 |

≤2.0 |

8.0~12.0 |

18.0~20.0 |

- |

- |

- |

Bal. |

310S |

≤0.08 |

≤1.5 |

≤2.0 |

19.0~22.0 |

24.0~26.0 |

- |

- |

- |

Bal. |

316L |

≤0.03 |

≤1.0 |

≤2.0 |

10.0~14.0 |

16.0~18.0 |

2.0~3.0 |

- |

- |

Bal. |

317L |

≤0.08 |

≤1.0 |

≤2.0 |

11.0~15.0 |

18.0~20.0 |

- |

- |

- |

Bal. |

420 |

0.15~0.4 |

≤1.0 |

≤1.0 |

- |

12.0~14.0 |

- |

- |

- |

Bal. |

430L |

≤0.05 |

≤1.0 |

≤1.0 |

- |

16.0~18.0 |

- |

- |

- |

Bal. |

440 |

0.9~1.25 |

≤1.0 |

≤1.0 |

≤0.6 |

16.0~18.0 |

≤0.75 |

- |

≤3.5 |

Bal. |

440C |

0.95~1.2 |

≤1.0 |

≤1.0 |

≤0.6 |

16.0~18.0 |

≤0.75 |

- |

- |

Bal. |

17-4PH (630) |

≤0.07 |

≤1.0 |

≤1.0 |

3.0~5.0 |

15.5~17.5 |

- |

3.0~5.0 |

0.15~0.45 |

Bal. |

|

Grade |

Chemical Composition(%) |

||||||

|---|---|---|---|---|---|---|---|

C |

Si |

Mn |

Ni |

Cr |

Mo |

Fe |

|

SCM415 |

0.20~0.24 |

0.15~0.35 |

0.60~0.85 |

≤0.25 |

0.90~1.2 |

0.15~0.30 |

Bal. |

4140 |

0.38~0.43 |

0.15~0.35 |

0.75~1.00 |

- |

0.8~1.1 |

0.15~0.25 |

Bal. |

4340 |

0.38~0.43 |

0.15~0.35 |

0.6~0.8 |

1.65~2.00 |

0.7~0.9 |

0.2~0.3 |

Bal. |

4365 |

0.62~0.66 |

0.15~0.30 |

0.6~0.8 |

1.65~2.00 |

0.7~0.9 |

0.2~0.3 |

Bal. |

SAE 52100 |

0.98~1.10 |

0.15~0.35 |

0.25~0.45 |

- |

1.3~1.6 |

- |

Bal. |

8620 |

0.17~0.23 |

0.15~0.35 |

0.6~0.9 |

0.4~0.7 |

0.4~0.65 |

0.15~0.3 |

Bal. |

4605 |

0.4~0.6 |

0.15~0.35 |

0.12~0.23 |

1.5~2.5 |

- |

0.2~0.5 |

Bal. |

42CrMo4 |

0.38~0.45 |

≤0.4 |

0.6~0.9 |

- |

0.9~1.2 |

0.15~0.3 |

Bal. |

100Cr6 |

0.95~1.1 |

0.15~0.32 |

≤0.4 |

- |

1.3~1.6 |

- |

Bal. |

8740 |

0.38~0.43 |

0.15~0.3 |

0.75~1.0 |

0.4~0.7 |

0.4~0.6 |

0.2~0.3 |

Bal. |

Grade |

Chemical Composition(%) |

|||||||||

|---|---|---|---|---|---|---|---|---|---|---|

C |

Si |

Mn |

Ni |

Cr |

Mo |

W |

V |

Co |

Fe |

|

M2(SKH51) |

0.78~0.88 |

0.2~0.45 |

0.15~0.4 |

≤0.3 |

3.75~4.5 |

4.5~5.5 |

5.5~6.75 |

1.75~2.2 |

- |

Bal. |

M2(SKH51) |

0.95~1.05 |

0.2~0.45 |

0.15~0.4 |

≤0.3 |

3.75~4.5 |

4.5~5.5 |

5.5~6.75 |

1.75~2.2 |

- |

Bal. |

T15(SKH10) |

1.5~1.6 |

0.15~0.4 |

0.15~0.4 |

≤0.3 |

3.75~5.0 |

≤1.0 |

11.75~13.0 |

4.5~5.25 |

4.75~5.25 |

Bal. |

M42(SKH59) |

1.0~1.15 |

≤0.65 |

≤0.4 |

- |

3.5~4.5 |

9.0~10.0 |

1.15~1.85 |

0.95~1.35 |

7.5~8.5 |

Bal. |

H13(SKD61) |

0.32~0.45 |

0.8~1.2 |

0.2~0.5 |

≤0.3 |

4.75~5.5 |

1.1~1.75 |

- |

0.8~1.2 |

- |

Bal. |

D2(SKD11) |

1.4~1.6 |

≤0.6 |

≤0.6 |

≤0.3 |

11.0~13.0 |

0.7~1.2 |

- |

≤1.1 |

- |

Bal. |

A2(SKD12) |

0.95~1.05 |

0.1~0.5 |

0.4~1.0 |

- |

4.75~5.5 |

0.9~1.4 |

- |

0.15~0.5 |

- |

Bal. |

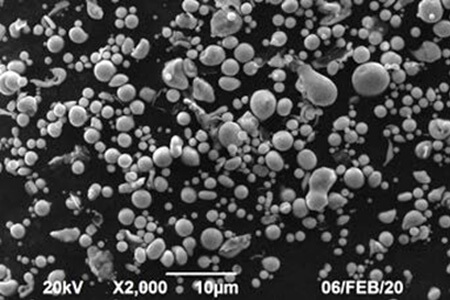

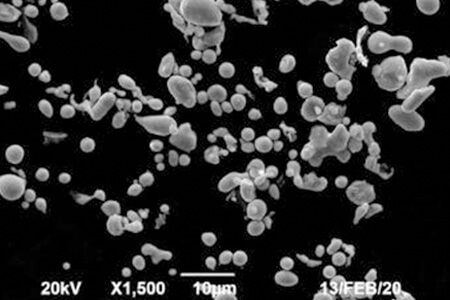

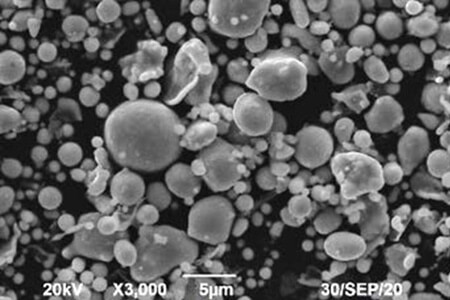

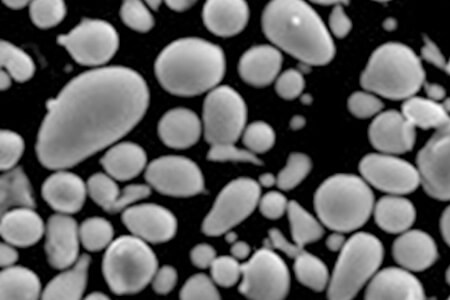

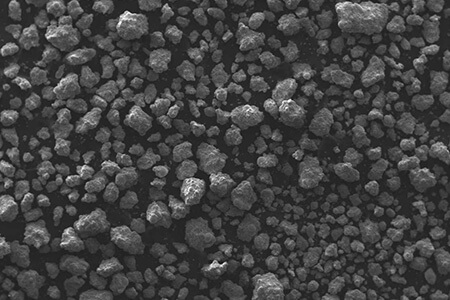

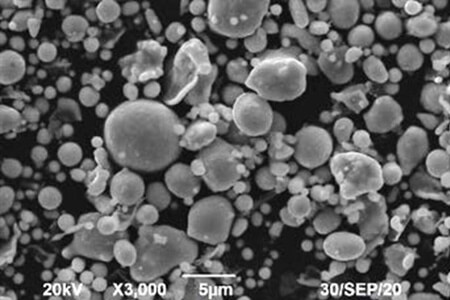

Small particle size、Good spherical morphology、High magnetic permeability、High Q value、Low coreloss、High saturation

Grade |

Chemical Composition(%) |

||

|---|---|---|---|

Si |

Cr |

Fe |

|

Fe-3Si |

2.5~3 |

- |

Bal. |

SF830 |

7.5~8.5 |

2.5~3.5 |

Bal. |

SF640 |

6~7 |

3.5~4.5 |

Bal. |

SF642 |

6~7 |

3.5~4.5 |

Bal. |

CMP (Curie Molding Powder) soft magnetic (alloy) coating powder is a finished powder that has been coated with anti-rust/insulating materials.

It is an application powder for one-piece inductors and can be directly pressed into molding; the powder has low iron (magnetic) loss, High magnetic permeability, high saturation and high withstand voltage (interlayer short circuit test), anti-cracking, anti-rust...etc.

CVHS Series |

Permeability |

Core Loss(mw/cc) |

l-sat |

Salt Spray |

TDS |

|---|---|---|---|---|---|

CVHS-45D01 |

45 |

<380 |

>65% |

24hr |

|

CVHS-40D01 |

40 |

<380 |

>70% |

24hr |

|

CVHS-26B01 |

26 |

<360 |

>85% |

48hr |

|

CVHH Series |

Permeability |

Core Loss(mw/cc) |

l-sat |

High temperature and |

TDS |

CVHH-48C01 |

48 |

<350 |

>70% |

1000hr |

|

CVHH-41C01 |

41 |

<350 |

>80% |

1000hr |

|

ASF Series |

Permeability |

Core Loss(mw/cc) |

l-sat |

Salt Spray |

TDS |

ASF-35M01 |

35 |

<400 |

>75% |

48hr |

|

ASF Series are semi-finished powders that have been coated with anti-rust insulation. The following electrical properties are the test results of compression molding after coating with 2.0% resin added to the magnet, for referertce only |

|||||

|

Part Number |

Dimension |

Inductance Range |

DCR Range |

Heat Rating Cur. |

l-sat |

||

|---|---|---|---|---|---|---|---|

|

CMC0412A-1R0NSA |

4.44 |

4.05 |

1.2 |

1.0 |

40-49.5 |

4.8 |

4.5 |

|

CMC0420AXXXXXX |

2.0 |

0.22-6.8 |

7.0-175.0 |

2.7-11.0 |

2.35-13.0 |

||

|

CMC0430A-XXXXXX |

3.0 |

0.22-4.7 |

7.0-75.90 |

3.5-11.5 |

3.5-15.5 |

||

|

Part Number |

Dimension |

Inductance Range |

DCR Range |

Heat Rating Cur. |

l-sat |

||

|---|---|---|---|---|---|---|---|

|

CMC0518A-XXXXXX |

5.4 |

5.2 |

2.0 |

1.0-1.5 |

1S.0-25.88 |

6.7*8.0 |

8.3~9.0 |

|

Part Number |

Dimension |

Inductance Range |

DCR Range |

Heat Rating Cur. |

l-sat |

||

|---|---|---|---|---|---|---|---|

|

CMC0630A-XXXXXX |

7.4 |

6.6 |

3.0 |

0.12-10.0 |

0.62-71.50 |

4.0-44.0 |

4.0-42.0 |

|

CMC0640A-XXXXXX |

4.0 |

0.15-2.2 |

0.96-15.84 |

10.0-35.0 |

10.0-46.0 |

||

|

CMC0642A-XXXXXX |

4.2 |

1.0-2.2 |

5.80-15.84 |

9.50-12.0 |

9.50-11.50 |

||

|

CMC0649A-XXXXXX |

4.9 |

0.18-0.47 |

0.75-2.85 |

20.0-40.0 |

20.0-40.0 |

||

|

Part Number |

Dimension |

Inductance Range |

DCR Range |

Heat Rating Cur. |

l-sat |

||

|---|---|---|---|---|---|---|---|

|

CMC0824A-R24XWA |

8.5 |

8.05 |

2.4 |

0.24 |

1.720-1.810 |

28.0 |

46.0 |

|

Part Number |

Dimension |

Inductance Range |

DCR Range |

Heat Rating Cur. |

l-sat |

||

|---|---|---|---|---|---|---|---|

|

CMC1020A-XXXXXX |

11.5 |

10.0 |

2.0 |

1.0-2.2 |

9.50-20.02 |

7.80-11.0 |

14.0-17.0 |

|

CMC1024A-XXXXXX |

2.4 |

2.2-3.3 |

17.0-22.55 |

7.0-8.50 |

11.0 |

||

|

CMC1030A-R22XWA |

3.0 |

0.22 |

1.00-1.05 |

34.0 |

34.0 |

||

|

CMC1040A-XXXXXX |

4.0 |

0.15-22 |

0.47-60.38 |

4.7-48.0 |

5.70-80.0 |

||

|

CMC1044A-XXXXXX |

4.4 |

0.22-22 |

0.62-69.08 |

4.5-40.0 |

4.50-56.0 |

||

|

CMC1055A-1R0FWA |

5.5 |

1.0 |

2.56-2.816 |

23.5 |

44.0 |

||

|

CMC1060A-2R2XSA |

6.0 |

2.2 |

3.85-4.235 |

21.0 |

20.0 |

||

|

CMC1065A-1R0XWA |

6.5 |

1.0 |

1.78-1.958 |

28.5 |

32.0 |

||

|

Part Number |

Dimension |

Inductance Range |

DCR Range |

Heat Rating Cur. |

l-sat |

||

|---|---|---|---|---|---|---|---|

|

CMC1040B-XXXXXX |

11.2 |

7.1 |

4.0 |

0.15-0.47 |

0.69-1.712 |

28.0-38.0 |

47.0-70.0 |

|

CMC1049B-XXXXXX |

4.9 |

0.22 |

0.61-0.662 |

40.0-43.0 |

50.0-60.0 |

||

|

CMC1050B-XXXXXX |

5.0 |

0.15-0.33 |

0.61-0.902 |

36.0-42.0 |

53.0-85.0 |

||

|

CMC1060B-XXXXXX |

6.0 |

0.15-0.30 |

0.52-0.968 |

32.0-42.0 |

55.0-80.0 |

||

|

Part Number |

Dimension |

Inductance Range |

DCR Range |

Heat Rating Cur. |

l-sat |

||

|---|---|---|---|---|---|---|---|

|

CMC1320A-XXXXXX |

13.8 |

12.8 |

2.0 |

2.2-3.3 |

17.0-24.20 |

6.50-8.50 |

9.0-10.50 |

|

CMC1324A-1R0XSA |

2.4 |

1.0 |

6.35-6.985 |

16.5 |

20.0 |

||

|

CMC1350A-XXXXXX |

5.0 |

0.68-20 |

1.10-31.56 |

6.20-40.0 |

8.50-50.0 |

||

|

CMC1360A-XXXXXX |

6.0 |

4.7-22 |

5.90-33.0 |

8.0-14.3 |

8.0-20.0 |

||

|

CMC1365A-XXXXXX |

6.5 |

4.7-220 |

5.90-283.30 |

2.2-14.3 |

1.80-20.0 |

||

|

CMC1380A-22RXSA |

8.0 |

22 |

30.50-33.55 |

7.0 |

7.0 |

||